Bolted Tanks

RTP, which stands for Rolled, Tapered Panel, is a key design in modern bolted steel storage tank construction. These tanks use rolled steel panels, about 108 inches long by 60 inches wide, with tapered edges for precise fitting. The panels are bolted together to form a vertical cylinder, with each set of connected panels called a “ring.” RTP tanks use lap joint panel connections with exact tolerances for a leak-free seal when combined with sealant. This design allows for tanks of various diameters and capacities, suitable for storing a range of liquids and dry materials. Phoenix Fabricators and Erectors, LLC boasts in-house design and engineering capabilities, including licensed professional engineers with deep industry expertise. As a single-source provider, Phoenix manages all aspects of tank construction—from design and engineering to fabrication, foundation installation, field construction, and more. This approach ensures strict quality control and attention to detail, resulting in high-quality storage tanks that meet or exceed client expectations.

-

Lower Upfront Installation Costs

-

From 20,000 to 10,000,000+ Gallons

-

Modern Bolted Steel Storage Construction

Modern Bolted Steel Storage Construction

Advantages and Features

PFE bolted tanks revolutionize industrial storage by offering a smarter alternative to conventional tank construction. These precision-engineered systems feature modular components manufactured in controlled facilities, enabling swift on-site assembly without extensive welding or labor costs. The streamlined installation process significantly reduces project timelines while maintaining exceptional quality standards.

The versatility of PFE tanks truly sets them apart in the marketplace. Whether storing water, chemicals, or bulk materials, these adaptable systems can be customized to meet specific industry requirements without sacrificing structural integrity. Businesses across sectors have embraced this innovative solution, recognizing the perfect balance of durability, efficiency, and reduced maintenance demands that bolted tanks provide.

- Safety:

Our tanks utilize synchronized jacking systems to keep our crew members on at

grade for the duration of the project. - Cost-Effective:

Lower shipping costs and reduced labor expenses due to simplified assembly. - Low Maintenance:

Requires minimal upkeep and typically has a longer lifespan than welded or

concrete tanks. - Customizable:

Available in various sizes and configurations to meet specific storage needs. - Quick Assembly:

Fast installation process compar

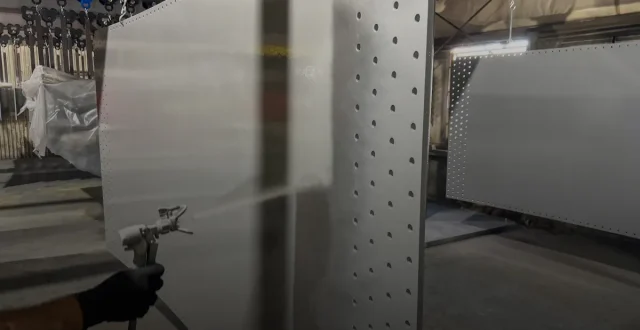

- Factory Coatings:

Available in multiple finishes, including NonoTec, epoxy coated, or

stainless steel for enhanced protection. - Leak-Proof Design:

Utilizes lap joint panel connections and sealants to ensure a water-

tight seal. - Modular Construction:

Built from individual steel panels that can be easily transported and

assembled on-site. - Robust Engineering:

Designed for durability, with heavy-duty construction suitable for

long-term performance. - NanoTec & Epoxy Diverse Applications:

Suitable for storing both liquids (water, wastewater, chemicals) and

dry materials – across various industries.