Composite Elevated Water Tanks

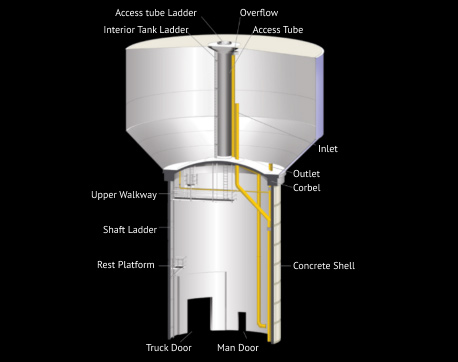

Composite tanks are increasingly becoming the desired choice for water storage. The consideration of aesthetics combined with long-term economics has lead to an increase of composite tanks, especially those with capacities greater than 500,000 gallons. The architectural concrete support pedestal creates a modern appearance and also creates additional space inside the base for other uses. If the concrete shaft is not painted, the composite tank design often provides a lower life-cycle cost than all-steel tanks primarily due to a reduction of paint surface area.

-

Pleasing

Aesthetic -

Lower Long Term Maintenance Cost

-

From 150,000 to 3,000,000 Gallons

Our proprietary 7-foot forming system is the most technologically advanced system in the industry. We utilize a solid interior platform that is self-elevating as the workers progress up the shaft. Through utilization of a solid platform, we use the safest forming system in the industry, which also allows ease of adjustment of each form back to the exact radius of the first lift dimension. The use of rustication strips creates an aesthetically pleasing appearance to the exterior of the shaft while the 7-foot form height provides a less cluttered look than smaller forming systems used by other manufacturers.

In addition to our proprietary 7-foot forming system, other innovative items that set Phoenix apart from the competition are as follows:

- Internal and external forms are tied together with thru-bolts to ensure wall thickness and alignment is maintained

- Corbels are pre-assembled during the manufacturing process to ensure exact compliance with the engineered plans and specifications d

- Monolithic pouring of the corbel and dome provides the tank owner with the best product available, as the cold joint at the interface of the tank and ring beam is eliminated

- Placement of bulkheads around the circumference of the shaft to segregate pours and reduce the potential of pour lines, thus improving the aesthetics of the support structure

- Platform is not used to support domes during placement, and remains approximately seven feet below the work level to provide a safer working environment

Download our Composite Elevated Tank Brochure

View our Composite Elevated Tank Standards

Download Composite Elevated Water Storage Tank Specifications

Featured Projects

At Phoenix Fabricators and Erectors, LLC, every project is unique. Our reputation for quality products is a result of over 30 years of providing the highest quality, most dependable water tanks for our customers